Leveraging TFP Hydrogen’s proprietary coating technology, the MPU is strategically designed to operate in close proximity to customers and component suppliers, streamlining the supply chain for PEM electrolyser manufacturers. By shortening the supply chain and optimising logistics, the MPU significantly augments response rates while ensuring uninterrupted operations. Furthermore, the MPU can be swiftly commissioned and fully operational within six to twelve months. This advancement underscores James Cropper’s commitment to bolstering the industry’s expansion and providing support to PEM electrolyser manufacturers.

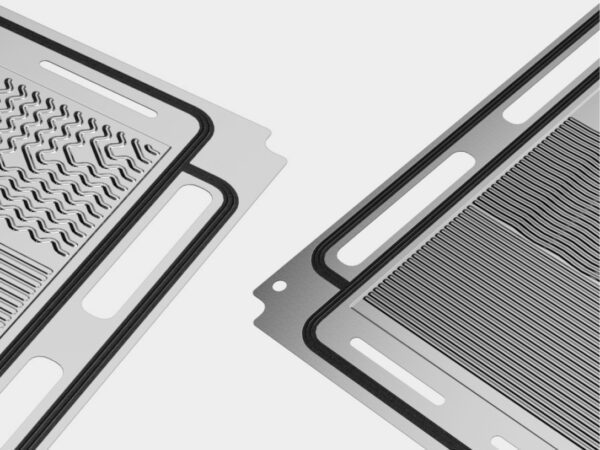

The coating technology developed by TFP Hydrogen and integrated within the MPU effectively addresses the material challenges associated with titanium components in PEM Electrolysers. These components included Porous Transport Layers, Bipolar and Unipolar plates as well as cell separators. The range of innovative coatings play a central role in enhancing the durability of the components, shielding against corrosion and minimising contact resistance; ultimately improving the overall operational efficiency and extending the lifetime of the electrolyser, thereby driving down long-term costs associated with green hydrogen production.